TOP CHARGING ELECTRIC ARC FURNACE

TOP CHARGING ELECTRIC ARC FURNACE

Top EAF chargingis convention type, from 0.5t to 200t, each capacity requires a bucket charge from the top. The first step in any EAF tap-to-tap cycle is "charging" into the scrap. The EAF roof and electrodes are raised and are swung to the side of the electric arc furnace chargingfurnace to allow the scrap EAF charging crane to move a full bucket of scrap into place over the EAF charging furnace. The bucket bottom is usually a clam shell design - i.e. the bucket opens up by retracting two segments on the bottom of the bucket. The scrap falls into the EAF charging furnace and the scrap crane removes the scrap bucket. The roof and electrodes swing back into place over the electric arc furnace charging furnace.

Electric arc furnace that uses the high temperature produced by electrode arc to melt ore and metal, DRI, HBI. When gas discharge forms an arc, this energy is very concentrated, and the temperature of the arc zone is above 3000 ℃. For metal smelting, electric arc furnaces have greater flexibility in the process compared to other steel-making furnaces, effectively removing impurities such as sulfur and phosphorus. The electric arc furnace charging furnace temperature is easy to control, and the equipment occupies a small area, making them suitable for the melting of high-quality alloy steel.

ADVANTAGES

CHNZBTECH TOP ELECTRIC ARC FURNACE CHARGING ADVANTAGES

EAF from CHNZBTECH, a professional EAF charging furnace supplier, is the ideal melting unit for the production of all types of steel, from standard carbon grades up to high-alloyed and stainless steel grades. Its overall EAF furnace performance can be additionally enhanced with the latest oxygen- and carbon-injection technologies. The idea of CHNZBTECH for the choice of the various systems making up the plant is strictly related to the achievement of the following high-priority objectives, namely:

Ultra High Power

High Efficiency

High-quality

High Flexibility to meet different needs

Less investment

FEATURES

FEATURES OF TOP ELECTRIC ARC FURNACE CHARGING

The energy required to meltdown and superheat the scrap and slag including all losses is balanced by the energy input by means of electrical energy and exothermic reactions. Electric Arc Furnace (EAF) is designed consider always for short tap-to-tap times because of several technologies such as:

Ultra-high power is the most prominent feature of the new generation of EAF charging equipment so that high secondary voltages and longer arc can be achieved.

Extensive use of alternative energy sources (chemical energy, like oxygen, and natural gas) by wall-mounted burners and manipulators from EAF charging furnace door.

With DRI/HBI top feeding by overhead belt, heavy construction design to sustain hard working conditions, allowing very fast movements and safe operations.

Know-how technology of electrode control system, hot heel and better skin-effect of copper-steel cladded electrode arm to improve melting.

CHNZBTECH, one of the professional steel furnacemanufacturers in China, manufactures industrial Steel Making Furnaces that are advanced and high-performance steel furnace types designed specifically for the steel making industry. The steel furnace for sale is constructed using high-quality material and is equipped with state-of-the-art technology to ensure efficient and reliable steel production.

在线联系供应商

Other supplier products

| VOD VACUUM OXYGEN DECARBURIZATION | VOD VACUUM OXYGEN DECARBURIZATIONVD/VOD Furnace The equipment structure of a VOD furnaceis basically the same as that of a VD vacuum refining fu... | |

| Secondary Refining Furnace | The steel refining process by secondary refining furnace can be divided into two categories: primary refining, aimed at removing carbon from pig ir... | |

| LOW CARBON FERROCHROME FURNACE | The main raw materials for smelting low-carbon ferrochromium using the electro silicothermic method include chromium ore, silicon chromium alloy, a... | |

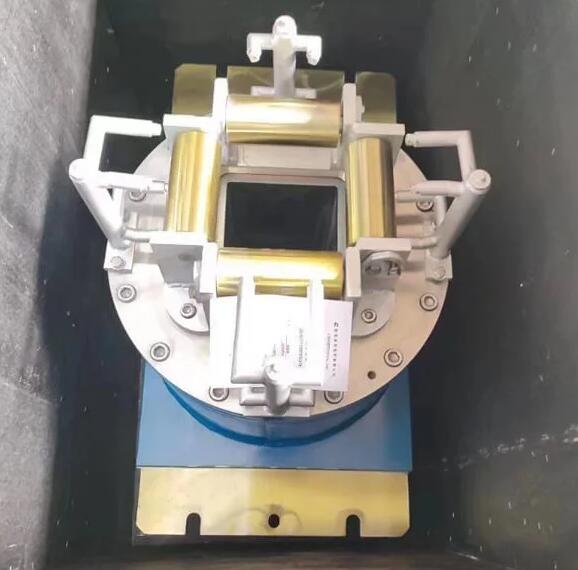

| COPPER MOLD ASSEMBLY | Cooper mould assemblyline is a continuous steel casting equipment that receives molten steel injected from the intermediate tank and solidifies it ... | |

| WATER-COOLED PANELS | CHNZBTECH, a professional water cooled panelssupplier, is committed to getting those standards, engineering and manufacturing water-cooled panels a... |

Same products

| Steel for Marine Use | 卖方: huaro-shanghai | General description of the best stainless steel for marine use Marine also is known as the shipb... | |

| Tinplate Sheet | 卖方: huaro-shanghai | Description of Tinplate Sheet Tinplate sheetrefers to the two sides coated with commercially pur... | |

| Tinplate Coil | 卖方: huaro-shanghai | Description of Tinplate Coil Tinplate is made from the cold-rolled sheet which is electroplated ... | |

| Steel Slab | 卖方: huaro-shanghai | Description of Steel Slab Steel slabis a thick flat steel sheet rolled and cooled from the CCM m... | |

| Steel Product | 卖方: huaro-shanghai | Importance of steel products list Steel is one of the oldest metals forged by humans and is stil... |