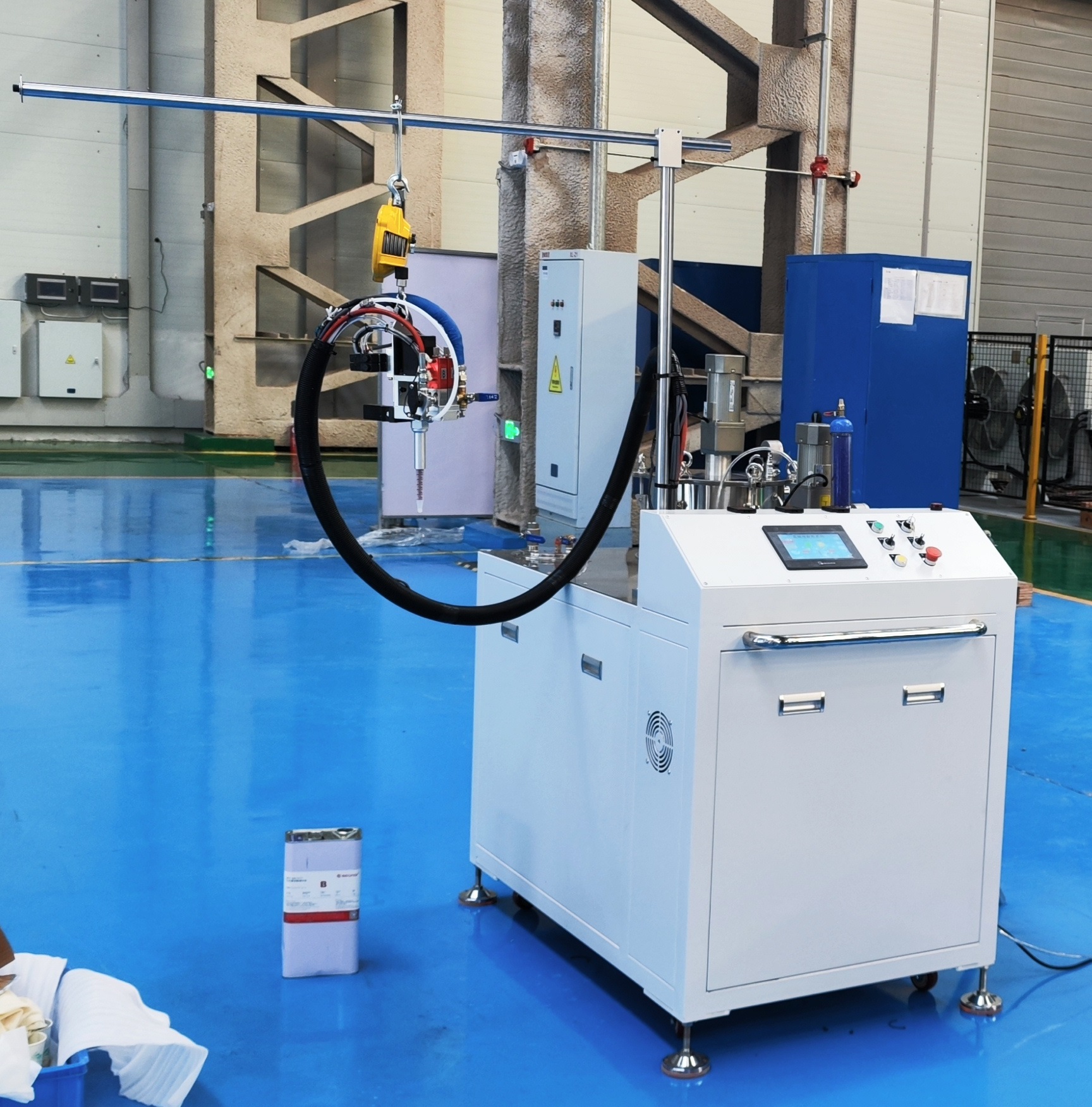

Epoxy Ab Glue Machine 2K Mixing and Dispensing Machine

ab glue mixing and dosing machine

Potting and encapsulation is the process of embedding products & assemblies in a liquid resin (potting compounds) to protect them against rough environment conditions. Potting can be performed in atmosphere pressure or even under vacuum, if high voltage insulation and high temperature differences are needed. Encapsulation of parts will stop corrosion of metals and reduce damage caused by vibration and mechanical stress.

We offer automatic ,se-mi automatic fluid dispensing potting machine and the related production line and vacuuming systems .

General description of the machine

our ab dosing dispensing machine precisely metering, mixing and dispensing two-component medium to low-viscosity materials for potting, dispensing ,sealing, casting ,encapsulation and filling.

For variable ratio dispensing, the system handles ratios from 1:1 to 10:1.

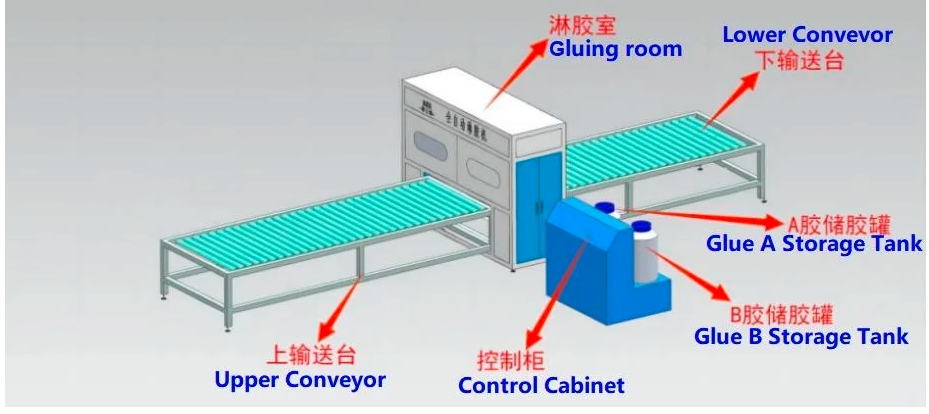

The system is composed of AB tanks, metering pumps and motor, mixing pipe, dual valve, dynamic motor for dynamic stirring and 3-axis robotic platform.

Two kinds of component materials are separately before they mix in mixing tube to avoid glue cure in system. Dispensing valve is with suck-back function to keep thin fluid from dripping.

Introduction :

1. Working Mode: controlled by PLC module and MCGS touch screen.

2.High precision valve: high speed, glue off clean, no glue drawing, no dropping.

Working principle :

Compound materials A & B are kept in two tanks separately. There are two sets of metering pumps inside the machine for metering A and B resin by setting ratio, draining out material individually from tank A & B. Liquid A & B mix with each other in the mixer pipe and dispensed out according to the programmable data.

1. Stainless panel vacuum pressure tank which can bear negative pressure of inner tank .

6 Tank with heater which can preheat materials to assure good flowability .

our Pump technology

Valve technology

1. Dynamic mixing with stirring detecting function that ensure glue mixing evenly .

2 Stainless design of the glue touch surface to capture more higher material compatibility .

3 Glue valve with flow-back prevent function that can prevent glue from dropping when stop gluing .

4 Sealing parts of rod shaft adopt imported parts to keep more higher durability .

5 The self-cleaning function make machine cleaning more easier that you needn't dis-assembly the parts to wash . Cleaning time and cleaning times could be set in the touch screen.

detecting function that detect the speed and running time of pumps to ensure the ratio reliability.

3 Adjustable gluing-out volume make sure glue A/B dispense out at the same time from glue valve to get better glue mixing effect .

4 Machine with gel resistance calculator , which prevent the mixture curing inside .

5 You can set single gluing-out and steady gluing-out function to meet up with your different process requirement .

6 Whole machine system and function is controlled by Panasonic PLC and MGCS touch screen .

7 Reserved PLC communication interface, which easy connecting with outside device .

8 Equipped with a safety lock to prevent staff from wrong operation ..

Send product request

Other supplier products

| Fully Automatic Glue Spraying Machine for Exterior Honeycomb Panel Fire-Proof Door Fefrigerated Truck Body Panels | Fully Automatic Glue Spraying Machine for Exterior Honeycomb Panel Fire-Proof Door Fefrigerated Truck Body Panels The glue Spraying line is ba... | |

| Sips sandwich panel glue spraying machine | The glue Spraying line is based on the reform of the traditionalroller glue machine process. With the marketization and standardscale of stainles... | |

| Automatic Glue Mixing and Potting Machine for LED driver | AB glue meter mix dispensing machine/automatic glue potting machine for LED driver automatic epoxy resin potting machine 2 Part Silicone plyureth... | |

| 2 parts fluid mixing dispenser 2 component dosing epoxy PU silicon rubber vacuum system | What is the difference between 2K AB adhesive materials manual potting machine and robot pottingmachine ? AutomaticAB potting machine is composed ... | |

| Two Components Epoxy Resin Ab Glue Meter Mixing Dispensing Machine Automatic Liquid Filling Glue Dispensing CNC Machine | Information about Meter Mixing/Dispensing Machines for 2-Part Polyurethane Casting Resins Two-part polyurethane casting resin systems may be proce... |

Same products

| Palm Oil Wastewater | Seller: Jiangsu Jiuwu Hi-tech Co., LTD | Palm Oil Wastewater Palm oil is not only the highest yielding cheap vegetable oil on the earth b... | |

| Food & Beverage | Seller: Jiangsu Jiuwu Hi-tech Co., LTD | Food & Beverage Ceramic membrane has high separation efficiency and good chemical stability,... | |

| Fruit And Vegetable Juice | Seller: Jiangsu Jiuwu Hi-tech Co., LTD | Fruit And Vegetable Juice APPLE JUICE Apple juice in the press process will bring a lot of impu... | |

| Organic Membrane | Seller: Jiangsu Jiuwu Hi-tech Co., LTD | Organic Membrane The organic membraneis a material having a selective separation function, and w... | |

| Ultrafiltration Ceramic Membrane Element | Seller: Jiangsu Jiuwu Hi-tech Co., LTD | JIUWUcompany produces the ceramic ultrafiltration membraneswith the pore size 20nm, 50nm and so o... |