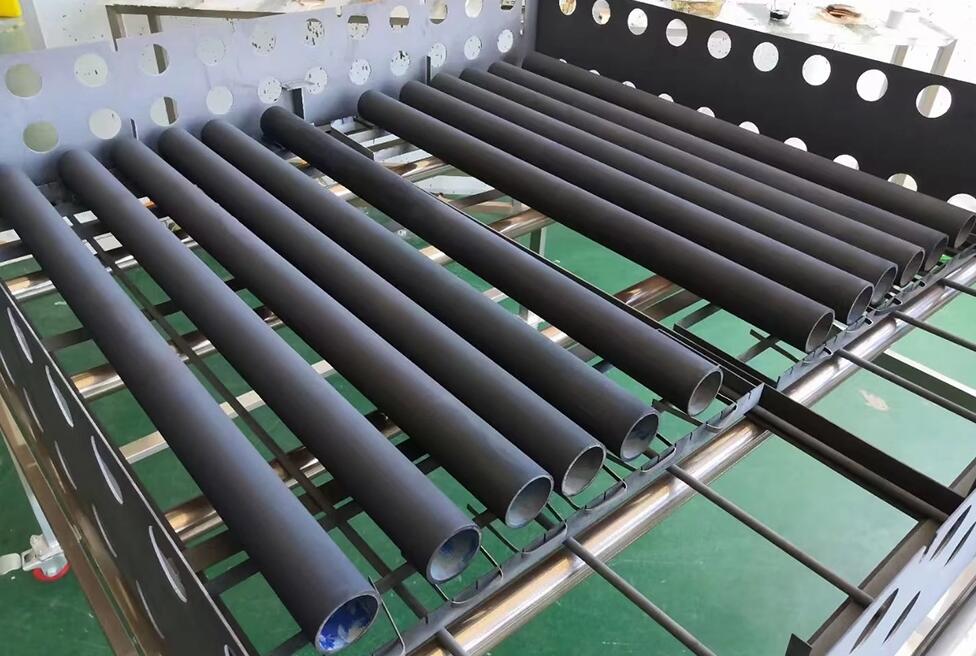

Molybdenum Rod

HSG molybdenum bar supplier provides the pure molybdenum bar for sale with molybdenum content greater than 99.95%.

Also, as a molybdenum rod supplier, we offer high temperature molybdenum rod (lanthanum molybdenum alloy rod) which contain lanthanum 0.4~1.2%, molybdenum content in addition to impurities.

TZM molybdenum rod :0.4~0.6Ti, 0.07~0.12Zr, 0.01~0.05C.

Application of Molybdenum Rod

Used for manufacturing electric vacuum devices and electric light source parts

Suitable for processing ion implantation parts

The molybdenum products can be used as high temperature heating body and high temperature structural parts

In the glass and refractory fiber industry used as furnace electrode, working in 1300℃ glass molten liquid, long life

Used as electrodes in rare earth industry

Features of Molybdenum Rod

Good corrosion resistance (The surface of moly rodis easy to produce a layer of dense natural protective film, It can be well to protect the matrix from corrosion by artificial anodic oxidation and coloring, good casting performance can be cast aluminum alloy or processing Plastic deformation of good aluminum alloy.)

High strength (molybdenum rod have the high strength.After a certain degree of cold processing can strengthen the matrix strength, some grades of molybdenum rod can also be enhanced by heat treatment).

Good thermal conductivity (The conductive thermal conductivity of molybdenum only less than the silver, copper and gold).

Easy processing (After add some certain alloying elements, you can get a good casting performance of aluminum alloy casting or processing plastic deformation of aluminum alloy).

As one of refractory metal suppliers, Huasheng Metal (HSG), established in 2003, which is based on Beijing, the capital of China, mainly engaged in the import-export and the domestic market about the metallurgical raw material and metallurgical products which include Ferro Alloys, Minor Metals, Sintered Steelmaking Metal Bars, Metal Scrap, Metal Ingot, and Tungsten products, Molybdenum products, Tantalum products, Niobium products, Ruthenium & Hafnium etc.

Send product request

Other supplier products

| Tungtsen Powder | Tungsten powderis the main raw material for processing powder metallurgy tungsten products and tungsten alloys. Pure tungsten powder can be made in... | |

| Tungsten Carbide Scrap | As one of tungsten carbide scrap suppliers, we offer tungsten carbide scrap for sale at good wholesale prices. Tungsten carbide scrap materials ca... | |

| Ferro Vanadium | Ferro vanadium is an iron alloy consisting of vanadium and iron, mainly used as an alloy additive in steelmaking. The main raw material of ferro ... | |

| Indium Ingot | CAS 7440 74 6 indium ingots for sale. Soft enough to score with your nails. Good ductility, no work hardening phenomenon during pressure process... | |

| Tungsten Metal Bar | Pure tungsten baris made of 99.95% tungsten powder. Its physical properties are as follows: density 19.3g/cm3, melting point (liquid) 3422°C, c... |

Same products

| Rare Earth | Seller: UrbanMines Tech. Limited | Cerium(Ce);Erbium(Er);Dysprosium(Dy);Europium(Eu) ;Gadolinium(Gd) ;Holmium(Ho);Lanthanum(La) ;Lut... | |

| Titanium Capillary Tube | Seller: Baoji City Changsheng Titanium Co.,Ltd | Normally titanium tubes with an outside diameter of less than 3mm as capillaries. The main raw ma... | |

| Titanium Bolt | Seller: Baoji City Changsheng Titanium Co.,Ltd | Titanium Bolts Wholesale Titanium bolts have the characteristics of low density, high specific s... | |

| Titanium Basket | Seller: Baoji City Changsheng Titanium Co.,Ltd | Titanium mesh basketis light in weight, has strong corrosion resistance, and has a layer of oxide... | |

| Titanium Anode & Electrode | Seller: Baoji City Changsheng Titanium Co.,Ltd | The procedure entails brushing, sintering, and electroplating. The coating's components and quant... |