Cassava Chips Cutting Machine

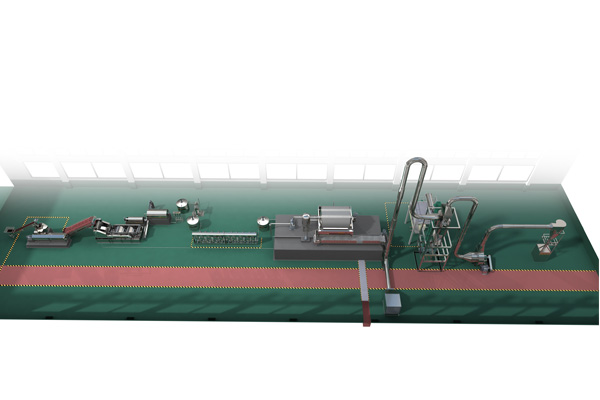

Cassava Chips Process Description and Flowchart:

Cassava chips are one kind of chips or slices made from fresh cassava roots, as snacks or animal feed popular in many countries of West Africa and the Caribbean.Goodway has 27 years of combined experience in the cassava slicer machineand cassava chips processing production line.

Multiple distinct operations are required in cassava chips processing: washing, peeling, slicing, chips drying and packaging.

We provide below a brief description of the main steps of the cassava chips productionprocess.

Cleaning and Washing Cassava Roots

Wash the fresh cassava roots in clean water to remove the surface mud and sand. It's the first step of cassava chips process and very important for the quality of final cassava slicer.

Peeling Cassava Roots

Peeling Cassava Roots

Peel the washed cassava roots to remove the outer brown skin and inner thick cream layer. The water source should be checked regularly to ensure it is not dirty or contaminated.

Cutting Cassava Roots into Wet Cassava Chips

Cutting Cassava Roots into Wet Cassava Chips

Cut the peeled cassava roots into chips by the high speed rotating circular cutter blade, then cut the chips into strips by the cross cutter blade.

Drying Wet Cassava Chips into Dried Cassava Chips

Drying Wet Cassava Chips into Dried Cassava Chips

Dry the wet cassava chips into dried cassava chips with low moisture content by the principle of heat transfer exchange.

Send product request

Other supplier products

| Fufu Machine | Fufu Process Description and Flowchart: Fufu (variants of the name include foofoo, fufuo, foufou) is a staple food with deep roots in Ghana's histo... | |

| Potato Starch Making Machine 2019 | Potato Starch Process Description and Flowchart: Goodway has been continuously developing potato starch making machine since 1991 to maximize produ... | |

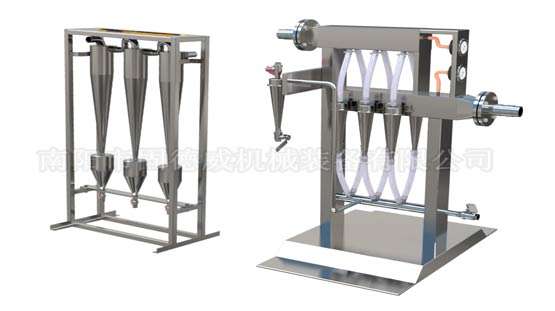

| Dewatering and Drying System | The section of dewatering and drying has come to final steps of cassava dewatering machine, the vacuum dehydrator can remove as much moisture as po... | |

| Cassava Washing Machine | The section of cassava washing machineis designed as the first steps of cassava starch processing, cassava flour processing, and garri processing, ... | |

| Centrifugal Dewatering Machine | Features of Centrifugal Dewatering Machine Processing Capacity: 1-10Tons/hour Application Scope: Cassava or potato starch dewatering Product Int... |

Same products

| Palm Oil Wastewater | Seller: Jiangsu Jiuwu Hi-tech Co., LTD | Palm Oil Wastewater Palm oil is not only the highest yielding cheap vegetable oil on the earth b... | |

| Food & Beverage | Seller: Jiangsu Jiuwu Hi-tech Co., LTD | Food & Beverage Ceramic membrane has high separation efficiency and good chemical stability,... | |

| Fruit And Vegetable Juice | Seller: Jiangsu Jiuwu Hi-tech Co., LTD | Fruit And Vegetable Juice APPLE JUICE Apple juice in the press process will bring a lot of impu... | |

| Organic Membrane | Seller: Jiangsu Jiuwu Hi-tech Co., LTD | Organic Membrane The organic membraneis a material having a selective separation function, and w... | |

| Ultrafiltration Ceramic Membrane Element | Seller: Jiangsu Jiuwu Hi-tech Co., LTD | JIUWUcompany produces the ceramic ultrafiltration membraneswith the pore size 20nm, 50nm and so o... |