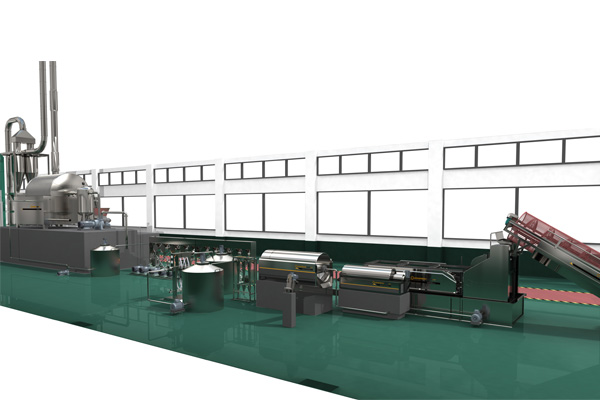

Cassava Chips Cutting Machine

Cassava Chips Process Description and Flowchart:

Cassava chips are one kind of chips or slices made from fresh cassava roots, as snacks or animal feed popular in many countries of West Africa and the Caribbean.Goodway has 27 years of combined experience in the cassava slicer machineand cassava chips processing production line.

Multiple distinct operations are required in cassava chips processing: washing, peeling, slicing, chips drying and packaging.

We provide below a brief description of the main steps of the cassava chips productionprocess.

Cleaning and Washing Cassava Roots

Wash the fresh cassava roots in clean water to remove the surface mud and sand. It's the first step of cassava chips process and very important for the quality of final cassava slicer.

Peeling Cassava Roots

Peeling Cassava Roots

Peel the washed cassava roots to remove the outer brown skin and inner thick cream layer. The water source should be checked regularly to ensure it is not dirty or contaminated.

Cutting Cassava Roots into Wet Cassava Chips

Cutting Cassava Roots into Wet Cassava Chips

Cut the peeled cassava roots into chips by the high speed rotating circular cutter blade, then cut the chips into strips by the cross cutter blade.

Drying Wet Cassava Chips into Dried Cassava Chips

Drying Wet Cassava Chips into Dried Cassava Chips

Dry the wet cassava chips into dried cassava chips with low moisture content by the principle of heat transfer exchange.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Cassava Peeling Machine | Features of Cassava PeelingMachine Processing Capacity: 4-6Tons/hour Application Scope: Fresh cassava peeling and washing Product Introduction: Cas... | |

| Cassava Chips Cutting Machine | Features ofCassava Chips Cutting Machine Cassava Chips Process Description and Flowchart: Cassava chips are one kind of chips or slices made fro... | |

| Dewatering and Drying System | The section of dewatering and drying has come to final steps of cassava processing, the vacuum dehydrator can remove as much moisture as possible a... | |

| Cassava Vibrating Sieve | Features of Cassava vibro sifter sieves Break the pressed cassava cakes into granules and separate the uniform size granules from the lumps to obt... | |

| Cassava Centrifugal Sieve | Features of Cassava Centrifugal Sieve The slurry is pumped directly to the center of the conical rotating screen basket. Under centrifugal force, ... |

Похожие товары

| MFS-160A 1-8KHZ 160KW 250A Medium Frequency Induction Heating Machine | Продавец: Chengdu Jinkezhi Electronic Co., Ltd | MFS-160A medium frequency induction heating machine inverter uses IGBT as the core component. The... | |

| MFS-120A 1-8KHZ 120KW 182A Medium Frequency Induction Heating Machine | Продавец: Chengdu Jinkezhi Electronic Co., Ltd | MFS 120A induction heating power supply adopts IGBT as the core component. As a medium frequency ... | |

| Medium Frequency Induction Heating Machine | Продавец: Chengdu Jinkezhi Electronic Co., Ltd | If you need hot forging for large workpieces, smelting for ferrous or non-ferrous metals or deep ... | |

| High Frequency Induction Heating Machine | Продавец: Chengdu Jinkezhi Electronic Co., Ltd | The working frequency of CX series ultra high frequency induction heating machinecovers 50KHZ ~ 1... | |

| CX2030C 50-120KHZ 30KVA 23A High Frequency Induction Heating Machine | Продавец: Chengdu Jinkezhi Electronic Co., Ltd | CX2030C 50-120KHZ high-frequency MOSFET type induction heater holds the output power of 15KW/30KV... |