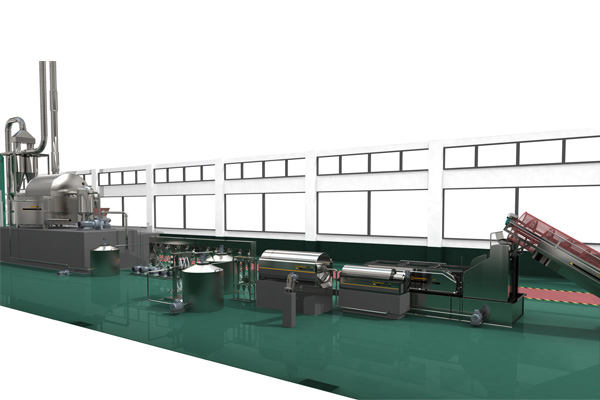

Cassava Starch Machine

Features of Cassava Starch Machine

Cassava (tapioca) Starch Processing Machine

Cassava (tapioca) Starch Process Description and Flowchart:

Goodway has been continuously developing cassava tapioca processing machinesince 1991 to maximize product quality. From cassava root hopper until the packaging stage, we can supply machines (tapioca processing machine) together with production process know-how.

The production process of cassava starch(tapioca) comprises the steps such as delivery and unloading cassava, washing, peeling, crushing, slurry and residues separation, desanding & desilting, starch concentrating and refining, de-watering, starch drying by using the starch drying machine, and packaging in the cassava starch plant.

As one of the most professional cassava starch manufacturers, we provide below a brief description of the main steps of the cassava starch(tapioca) production process. To meet the demands of cassava starch market, we offer the cassava starch making machine, also known as the tapioca starch machine.

Note: Goodway updates the cassava starch manufacturing machineryand cassava starch production line technology and machinery based on the latest experience.

Cleaning and Washing Cassava (tapioca) Roots

Wash the fresh cassava (tapioca) roots in clean water to remove the surface mud and sand. It's the first step of cassava starch process and very important for the quality of final cassava starch(tapioca).

Peeling Cassava (tapioca) Roots

Peel the washed cassava (tapioca) roots to remove the outer brown skin and inner thick cream layer. The water source should be checked regularly to ensure it is not dirty or contaminated.

Crushing Peeled Cassava (tapioca) Roots into Slurry

Crushing the peeled cassava (tapioca) roots into the slurry and separate to remove the coarse cassava residues to obtain uniformly smooth cassava slurry. The crushing drum and all food contact areas should be made from stainless steel.

Cassava (tapioca) Slurry and Residues Separation

The commonly physical operation to separate fine cassava residues from cassava slurry. Oversize particles of cassava residues cannot pass through the lattice structure of the filter, while fluid and small particles of cassava slurry can pass through to become filtrate.

Raw Starch Milk Desanding and Desilting

Solid control equipment that separates tiny sand and mud from the raw starch milk. Desander is installed before the desilter and normally the solids diameter for desander to be separated would be larger than for desilter.

Starch Refining and Concentrating

When raw starch milk enters the hydrocyclone, the pure starch milk of high density getting larger centrifugal force leaves from the underflow outlet, and the protein and other soluble impurities of low density getting smaller centrifugal force leave from the overflow outlet. Finally, achieve the purpose of various components of separation, and improve the quality of final starch with higher whiteness and purity.

Pure Starch Milk De-watering

De-watering the pure starch milk to low water content of 35-40% by the principle of vacuum suction filtration. Ensure sufficient water has been removed, otherwise, the starch will form into lumps during drying.

Drying Wet Starch into Dried Starch

Effectively dry the wet starch into dried starch(tapioca) with low moisture content by the principle of heat transfer exchange. The drying process is more reliable and of higher quality.

在线联系供应商

Other supplier products

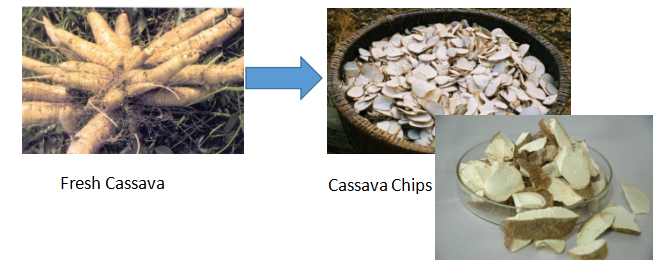

| Cassava Chips Machine 2019 | Cassava Chips Processing Description and Flowchart: Cassava chips are one kind of chips or slices made from fresh cassava roots, as snacks or anim... | |

| Potato Starch Making Machine | Features of Potato Starch Making Machine Potato Starch Making Machine Potato Starch Process Description and Flowchart: Goodway has been contin... | |

| Rotary Vacuum Filter | Features of Rotary Vacuum Filter Processing Capacity: 0.2-0.3Tons/h/m2 Application Scope: Cassava or potato starch dewatering Product Introduction:... | |

| Centrifugal Dewatering Machine | Features of Centrifugal Dewatering Machine Processing Capacity: 1-10Tons/hour Application Scope: Cassava or potato starch dewatering Product Int... | |

| Fufu Machine | Features of Fufu Machine Fufu making machine for sale- Make Fufu(foofoo) from Fresh Cassava Fufu Machine Fufu Process Description and Flowch... |

Same products

| Brown Fused Alumina For Abrasive | 卖方: ZHENGZHOU HAOYUN NEW MATERIAL TECHNOLOGY CO., LTD. | Cooled and smelted under an electric arc at a high temperature above 2000 degrees, brown fused al... | |

| Brown Fused Alumina | 卖方: ZHENGZHOU HAOYUN NEW MATERIAL TECHNOLOGY CO., LTD. | What is brown fused alumina Brown fused alumina is a versatile product available in various form... | |

| Ceramic Kitchen Knife Set | 卖方: Yangjiang Bohao ENTERPRISE CO., LTD | Ceramic Kitchen Knife Set This ceramic knife setof 4 knives with a peeler set is enviably stylis... | |

| Magnetic Welding Holders | 卖方: NingBo BeiLun Meank Magnetics Co.,ltd. | We have different types of magnetic welding holder for saleat Meank China welding magnetic hook f... | |

| Dust Test Chamber | 卖方: Xi’an LIB Environmental Simulation Industry | LIB Industry offers a wide range of dust test chambers with different sizes and configurations to... |