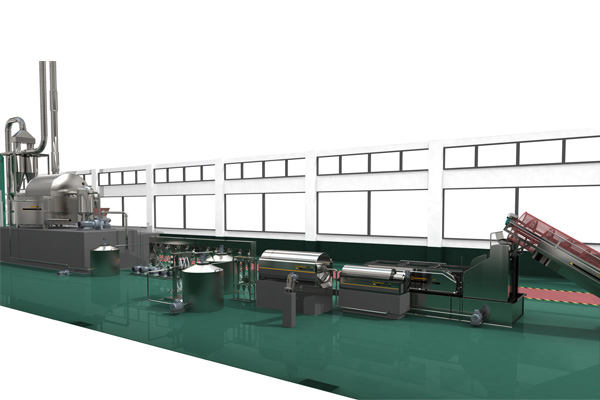

Cassava Starch Machine

Features of Cassava Starch Machine

Cassava (tapioca) Starch Processing Machine

Cassava (tapioca) Starch Process Description and Flowchart:

Goodway has been continuously developing cassava tapioca processing machinesince 1991 to maximize product quality. From cassava root hopper until the packaging stage, we can supply machines (tapioca processing machine) together with production process know-how.

The production process of cassava starch(tapioca) comprises the steps such as delivery and unloading cassava, washing, peeling, crushing, slurry and residues separation, desanding & desilting, starch concentrating and refining, de-watering, starch drying by using the starch drying machine, and packaging in the cassava starch plant.

As one of the most professional cassava starch manufacturers, we provide below a brief description of the main steps of the cassava starch(tapioca) production process. To meet the demands of cassava starch market, we offer the cassava starch making machine, also known as the tapioca starch machine.

Note: Goodway updates the cassava starch manufacturing machineryand cassava starch production line technology and machinery based on the latest experience.

Cleaning and Washing Cassava (tapioca) Roots

Wash the fresh cassava (tapioca) roots in clean water to remove the surface mud and sand. It's the first step of cassava starch process and very important for the quality of final cassava starch(tapioca).

Peeling Cassava (tapioca) Roots

Peel the washed cassava (tapioca) roots to remove the outer brown skin and inner thick cream layer. The water source should be checked regularly to ensure it is not dirty or contaminated.

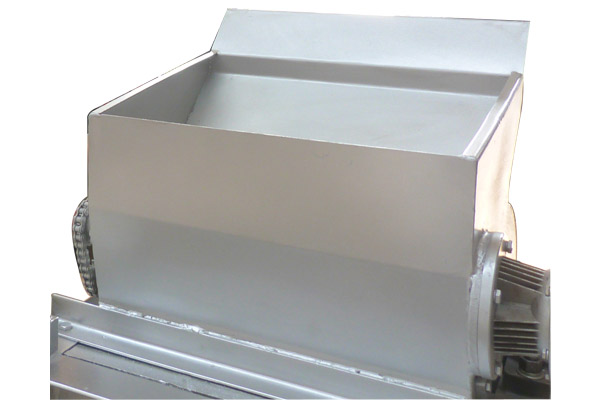

Crushing Peeled Cassava (tapioca) Roots into Slurry

Crushing the peeled cassava (tapioca) roots into the slurry and separate to remove the coarse cassava residues to obtain uniformly smooth cassava slurry. The crushing drum and all food contact areas should be made from stainless steel.

Cassava (tapioca) Slurry and Residues Separation

The commonly physical operation to separate fine cassava residues from cassava slurry. Oversize particles of cassava residues cannot pass through the lattice structure of the filter, while fluid and small particles of cassava slurry can pass through to become filtrate.

Raw Starch Milk Desanding and Desilting

Solid control equipment that separates tiny sand and mud from the raw starch milk. Desander is installed before the desilter and normally the solids diameter for desander to be separated would be larger than for desilter.

Starch Refining and Concentrating

When raw starch milk enters the hydrocyclone, the pure starch milk of high density getting larger centrifugal force leaves from the underflow outlet, and the protein and other soluble impurities of low density getting smaller centrifugal force leave from the overflow outlet. Finally, achieve the purpose of various components of separation, and improve the quality of final starch with higher whiteness and purity.

Pure Starch Milk De-watering

De-watering the pure starch milk to low water content of 35-40% by the principle of vacuum suction filtration. Ensure sufficient water has been removed, otherwise, the starch will form into lumps during drying.

Drying Wet Starch into Dried Starch

Effectively dry the wet starch into dried starch(tapioca) with low moisture content by the principle of heat transfer exchange. The drying process is more reliable and of higher quality.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| China Potato Peeling Machine | With the development of food industry, food deep processing has been paid more and more attention by the world, especially in the birth of instant ... | |

| Potato Starch Making Machine | Features of Potato Starch Making Machine Potato Starch Making Machine Potato Starch Process Description and Flowchart: Goodway has been continuous... | |

| Cassava Flour Milling Machine | Features of Cassava Flour Milling Machine Processing Capacity: 400-500kgs/hour Application Scope: Milling the coarse powder into fine powder Produ... | |

| Cassava Grinding Machine | Goodway is the manufacturer and supplier of cassava processing machine, focus on providing the whole range of equipment for the cassava processing ... | |

| Фуфу Fufu Machine | Кухонный прибор, используемый для растирания приготовленных крахмалистых овощей, в частности маниоки, бананов или ямса, в западную и Центральную аф... |

Похожие товары

| Catalyst System & Auxiliary | Продавец: reformchem | Custom catalystsystem & auxiliary can industrialize many new chemical reactions to provide mo... | |

| Golfcart Battery | Продавец: Shenzhen Worldpower Energy Storage Technology Co.,Ltd | The Golfcart Battery is an essential and dependable energy solution specifically tailored for gol... | |

| Electric Scooter Battery | Продавец: Shenzhen Worldpower Energy Storage Technology Co.,Ltd | A cutting-edge power solution for your electric scooter. Engineered with advanced technology, our... | |

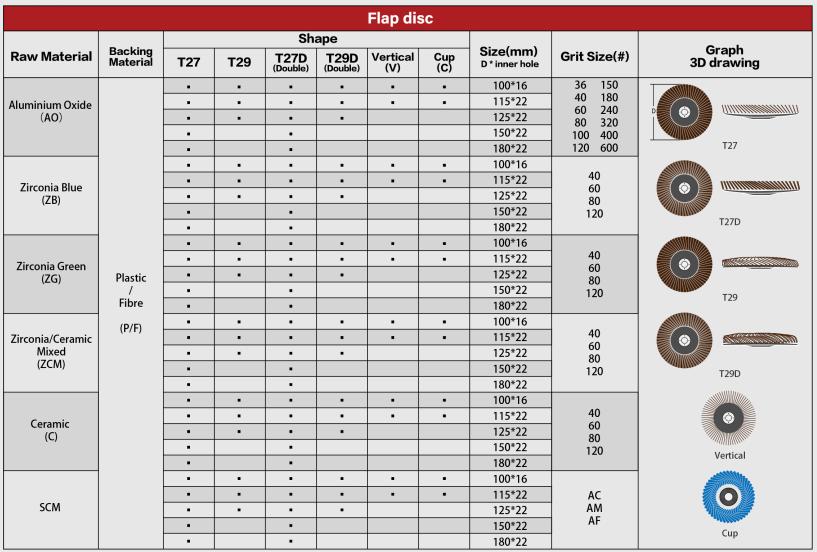

| Flat T27 Non Woven Flap Disc | Продавец: Keying Abrasives | The non-woven 75mm flap discis stuck to a glass-fabric backing pad, meaning that the discs can be... | |

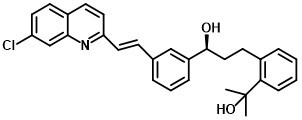

| Montelukast Sodium | Продавец: Lepu Medical Technology(Beijing)Co.,Ltd | *Product registration and availability vary by country. For more information on product availabil... |