LRF LADLE REFINING FURNACE

LRF ladle refining furnace is the most widely used refining equipment outside the furnace at present. The LRF furnace is used to refine the molten steel melted in the primary furnace, and can adjust the molten steel temperature and buffer the process.

The ladle furnace refiningequipment has many advantages, such as reasonable equipment structure, reliable operation, low cost, many refined steel types, high quality and convenient operation.

FUNCTIONS

CONDITIONS AND FUNCTIONS OF LRF IN STEEL MAKING

The LF furnace specification is from 8t to 300t, and has the following conditions and functions:

The working conditions in the LRF steelmaking furnace are reducing atmosphere and micro positive pressure;

The electrode adjustment mode of the industrial furnace ladleis three arm three-phase electrode adjustment;

The thermodynamic condition of the ladle heating furnace is graphite electrode arc heating;

The dynamic condition is argon stirring at the bottom of the ladle;

Add a certain amount of scrap crushing material into the ladle, heat it up with electric arc, measure the temperature and take samples to make the temperature control accurate, so as to optimize the pouring temperature;

Bottom blowing argon stirring to make the temperature of molten steel uniform, the composition uniform and the molten steel pure;

Slagging to remove sulfur and inclusions in molten steel;

Adjust the alloy composition and use the alloy feeding system to make the composition control accurate and the molten steel meet the final required chemical composition;

Wire feeding treatment: directly feed various wires into molten steel with a wire feeder, which can significantly improve the yield of alloy;

Smoke exhaust and dust removal. Equipped with a smoke exhaust and dust removal system, it can effectively control the smoke discharge and make the smoke emission meet the requirements of environmental protection;

As the ladle refining equipment outside the ladle arc furnace between the primary refining furnace and the continuous caster, it plays a buffer and regulating role in the production process of the whole workshop to ensure that molten steel with qualified temperature and composition is provided to the continuous caster.

STRENGH

LRF LADLE REFINING FURNACE FEATURES

LRF Ladle Refining Furnace Features

The features of the LRF furnace are as follow:

Electrode rotation dual station;

Ladle turret dual station technology;

Online wire feeding technology;

Automatic temperature measurement and sampling technology;

The technology of adding scrap steel to refining furnace;

Argon blowing automatic control technology;

LF one touch steelmaking technology.

We provide lrf steel making, lrf in steel making, ladle refining furnace process, ladle arc furnace, ladle furnace steelmaking, etc. For more information about types of furnace used in steel plant, please feel free to contact us!

Send product request

Other supplier products

| WATER-COOLED PANELS | CHNZBTECH, a professional water cooled panelssupplier, is committed to getting those standards, engineering and manufacturing water-cooled panels a... | |

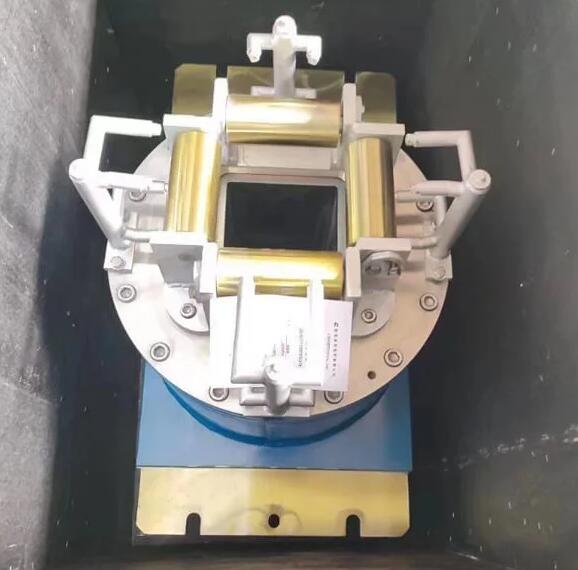

| COPPER MOLD ASSEMBLY | Cooper mould assemblyline is a continuous steel casting equipment that receives molten steel injected from the intermediate tank and solidifies it ... | |

| Secondary Refining Furnace | The steel refining process by secondary refining furnace can be divided into two categories: primary refining, aimed at removing carbon from pig ir... | |

| TOP CHARGING ELECTRIC ARC FURNACE | TOP CHARGING ELECTRIC ARC FURNACE Top EAF chargingis convention type, from 0.5t to 200t, each capacity requires a bucket charge from the top. The ... | |

| COPPER CLADDED ELECTRODE ARM | The conductive electrode armis a new type of cross arm made of copper steel composite plate or aluminum steel composite plate, with a rectangular c... |

Same products

| Frac PU Layflat Hose | Seller: SUZHOU SEAPEAK CO.,LTD | The outer cover of our PU layflat hose has been produced with extra thickness for tough environme... | |

| SDS-05030 0.50mm Diameter 30mm Length Glued Steel Fiber | Seller: Tengzhou Star Smith Metal Products Co.,Ltd | This kind of steel fiber is made of high-speed wire, when you add it to concrete, which can impro... | |

| SDS Micro Copper Coated Steel Fiber | Seller: Tengzhou Star Smith Metal Products Co.,Ltd | Micro brass fibers are made of copper coated steel wire , which is the most important materials o... | |

| SDS Loose Hooked End Steel Fiber | Seller: Tengzhou Star Smith Metal Products Co.,Ltd | Hooked end steel fibres are made of high-quality cold drawn steel line, in order to make sure tha... | |

| SDS Glued Hooked End Steel Fiber | Seller: Tengzhou Star Smith Metal Products Co.,Ltd | Glued hooked end steel fibre is made of high quality cold-drawn wire. The glued steel fiber in bu... |